ELDON JAMES Connector MATERIAL QUICK REFERENCE

MATERIAL SELECTION

Begin by checking the Chemical Resistance Chart. This chart provides a general reference for establishing compatibility between our PVC-free plastic materials and various chemicals. Note: The chart is for reference only – we strongly recommend testing to a standard that takes into account the actual chemical concentrations and environmental conditions specific to your application.

Please contact us for free testing samples.

NATURAL MATERIALS

ACETAL (AC)

Acetal is Opaque white in color with high stiffness, toughness and high wear resistance due to naturally high lubricity. Excellent long-term dimensional stability with high creep and fatigue resistance. Resistance to alcohols, esters, ketones, and aliphatic/aromatic hydrocarbons. Medical grade material with USP Class VI and ISO 10993-5 (cytotoxicity) ratings. Compliant to FDA 21 CFR 177.2470, Regulation No. 10/2011, REACH EC 1907/2006, Europe Decision 2001/2/EC:TSE, BSE – No Animal Origin and Phthalate/Latex/BPA free.

CRYSTALVU™ (CVU)

CrystalVu™ (polyolefin): A clear transparent alternative to polycarbonate containing no Bisphenol-A (BPA). These BPA-free plastic fittings will not deform at temperatures to 180 °C (356 °F). Autoclavable with enhanced characteristics compared to polycarbonate that includes: Superior chemical resistance, no crazing with multiple autoclave cycles, plus gamma and EtO Sterilization compatibility. RoHS compliant, USP Class VI, EU 2002/72/EC.

ENGAGE™ 8402 (E8402)

A POE copolymer that offers excellent performance as it is durable and flexible. Parts molded in this material provide high clarity. The materials low density can reduce the weight of end products. E8402 is the perfect material for bag ports as the port will flex with the bag film rather than being a rigid material working against the bag film. The barb will also flex giving our parts an advantage over other brittle materials that could crack with sideload.

HIGH DENSITY POLYETHYLENE (HDPE)

HDPE complies with FDA 21 CFR 177.1520 when used unmodified for the manufacture of food contact articles. HDPE has various applications for use in medical products and devices. It has excellent resistance to chemicals but exhibits lower thermal resistance than other materials. It is a softer material than nylon or polypropylene and much softer than Kynar®. RoHS compliant.

NATURAL KYNAR® (NK7)

Natural Polyvinylidene Fluoride (PVDF) resin features translucent, off-white hemispheres. RoHS-compliant, animal derivative-free, and PFAS-free. High stability in harsh thermal, chemical, and ultraviolet environments. High toughness and mechanical strength, low permeability, abrasion-resistant. Material with high barrier properties, high purity and good mechanical and thermal properties. Abrasion, impact, flame and corrosion, chemical and UV resistance. Kynar material can be autoclaved to 285 °F (140 °C) and meets USP Class VI requirements. Generally, these plastic fittings are chemically resistant to most acids, salts, weak bases, halogenated solvents, alcohols, nuclear and UV radiation, oxidants, ozone, and deionized water. Europe Decision 2001/2/EC:TSE, BSE – No Animal Origin and Phthalate/Latex/BPA free. USP Class VI, and various FDA and USDA certifications.

NYLON – NATURAL (NN)

Nylon exhibit good tensile strength, moderate stiffness, and high impact resistance. Material is resistant to many chemicals, fuels, oils, lubricants and solvent, but vulnerable to attack by phenols, strong acids, and oxidizing agents.

NYLON – MEDICAL (MN)

Nylons exhibit good tensile strength, moderate stiffness, and high impact resistance. They’re resistant to fuels, lubricants and many chemicals, but vulnerable to attack by phenols, strong acids, and oxidizing agents. (MN) White Medical Nylon is made from the same resin as Natural Nylon but has an FDA compliant white colorant added. RoHS compliant.

POLYCARBONATE (PC)

Polycarbonate fittings exhibit the same physical and chemical resistance properties as Natural Kynar®. PVDF fittings contain recycled runner material produced from virgin material, Natural Kynar® runs. For applications that do not require lot traceability or a material that meets USP Class VI requirements, PVDF fittings represent an excellent value.

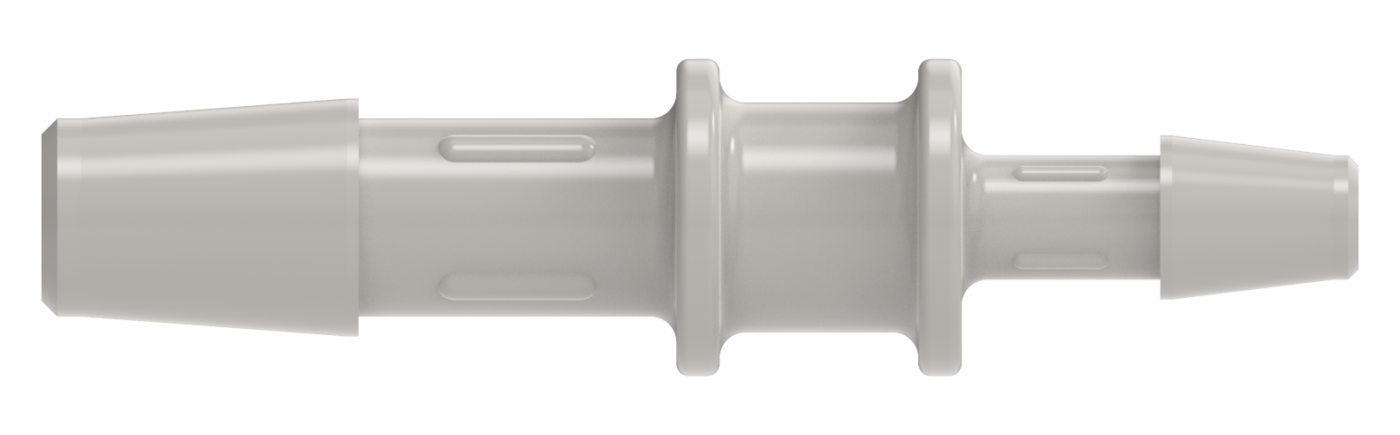

POLYPROPYLENE (PP) – ANIMAL DERIVATIVE FREE

Translucent in color produced without animal derived components. Material can be sterilized with radiation, ETO, and autoclave(1) methods. Excellent single use / limited reuse material for economy and Medical grade material with USP Class VI, USP 85, USP 88, USP 661 ratings and ISO 10993-5 (cytotoxicity) ratings. It resists most strong mineral acids and bases; however, it is subject to attack by oxidizing agents. Compliant to FDA 21 CFR 177.1520(a) and (c). Europe Decision 2001/2/EC:TSE, BSE – No Animal Origin and Phthalate/Latex/BPA free.

POLYSULFONE (PS)

Polysulfone is tough, rigid, high strength material suitable for continuous use at 300°F. Withstands oxidation, hydrolysis, prolonged high temperature exposure and repeated sterilization. Resistance to mineral acids, alkali and salt solutions, detergents and hydrocarbon oils. May be attacked by ketones, chlorinated hydrocarbons and aromatic hydrocarbons. Europe Decision 2001/2/EC:TSE, BSE – No Animal Origin and Phthalate/Latex/BPA free. Compliant to FDA 21 CFR177.1655 and approved by the NSF.

INDUSTRIAL / AUTOMOTIVE MATERIALS

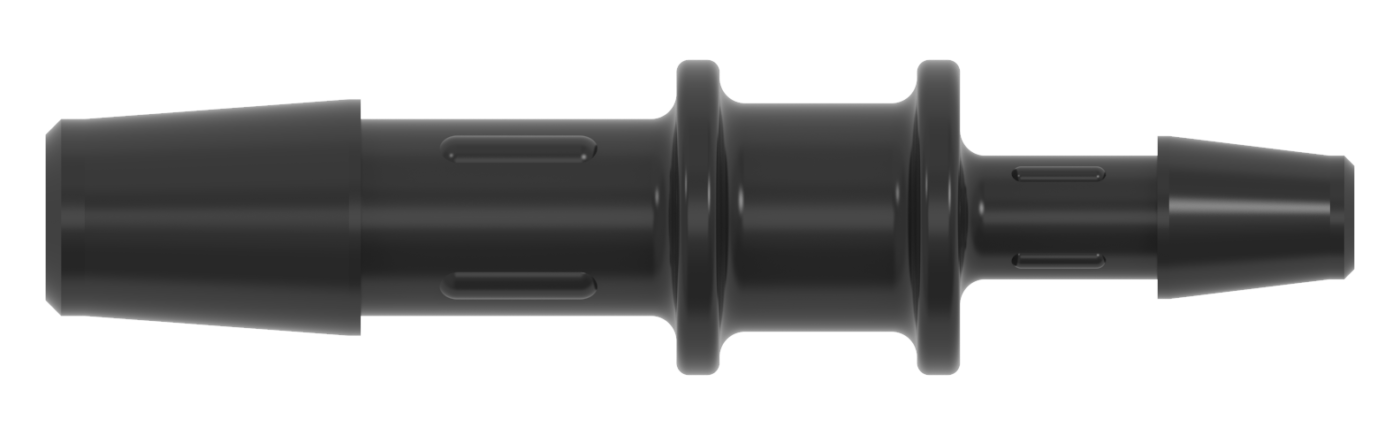

BLACK NYLON (BN)

Made from 6/6 nylon, black nylon fittings exhibit strength, moderate stiffness, high service temperature, high impact resistance, and tensile strength. Resistant to fuels, lubricants and many chemicals, but vulnerable to attack by phenols, strong acids, and oxidizing agents. RoHS compliant. Used in fuel lines, vacuum systems, and general-purpose applications. Automotive industry approvals.

GM……………………………………..GMP.PA66.062(N)

Ford…………………………………..(ESA-M4D379-A&B) WSK-M4D666-A

DCX……………………………………DB41 CPN2565

Delphi………………………………DCM5150

Other Approvals:…SAEJ1639PA0172, ASTMD4066PA0181

Temperature Range -50 °F to 275 °F (135 °C) • Pressure 150 psi @ 70 °F

GLASS-FILLED BLACK NYLON (GFBN)

GFBN is a standard material used in automotive and marine under-the-hood, heater and coolant applications. Gloss black in color with extremely high stiffness, impact resistance and wear resistance. Material can handle high stress loading at elevated temperatures and lower strains. Resistance to fuels, lubricants and many chemicals but may be vulnerable to attack buy phenols, strong acids and oxidizing agents. Compliant to PROP65, REACH 191, EU Directive 2011/65/EC Restriction of Hazardous Substances (RoHS), EU Directive 2003/11/EC, and EU Directive 2015/863-ROHS. Automotive industry approvals.

GM……………………………………GMP.PA66.013

Ford………………………………….WSK-M4D663-A

Other Approvals:………………ASTMPA12G35

Temperature Range -50 °F to 275 °F (135 °C) • Pressure 150 psi @ 70 °F Heat Deflection Temperature – ASTM D64: 475 °F (246 °C) @ 264 psi

GRAY KYNAR (PVDF)

Gray PVDF fittings exhibit the same physical and chemical resistance properties as Natural Kynar®. PVDF fittings contain recycled runner material produced from virgin material, Natural Kynar® runs. For applications that do not require lot traceability or a material that meets USP Class VI requirements, PVDF fittings represent an excellent value.

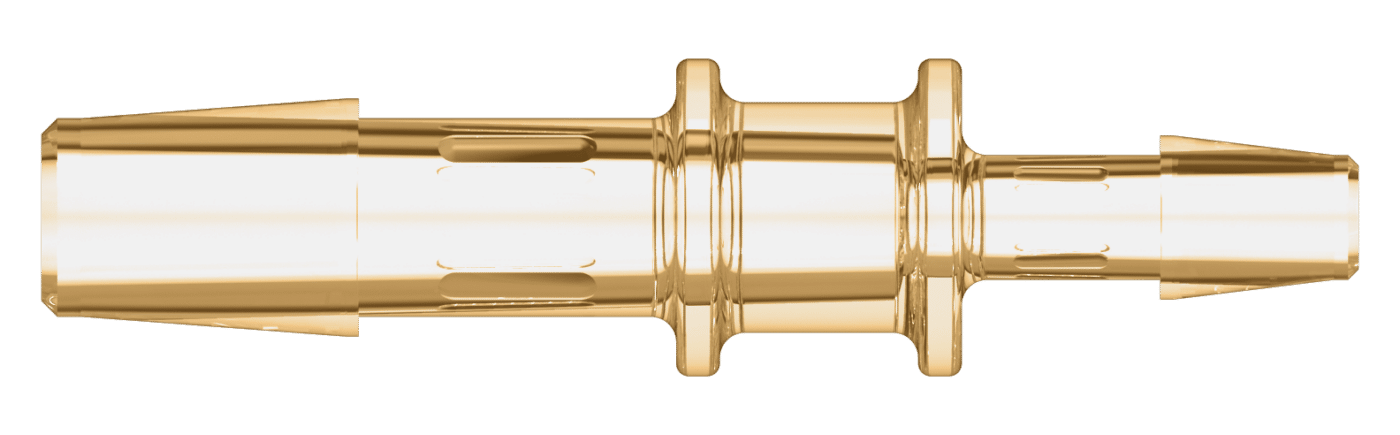

STAINLESS STEEL (SS)

Fittings produced with 316L alloy perform well in high temperature, harsh physical environments. 316L molybdenum-bearing stainless steel has excellent impact and chemical resistance but is less resistant than other types of stainless steel to highly oxidizing acids, such as nitric acid. RoHS compliant. The material has wide application in pharmaceutical and dairy processing and is used extensively for fittings in the brewery, beverage and bioprocess industries.

WHITE POLYPROPYLENE (WP)

White Polypropylene has the same physical and chemical resistance properties as Natural Polypropylene but is less expensive. WP fittings contain recycled runner material produced during virgin material, Natural Polypropylene production runs. White Polypropylene fittings are manufactured to the same tolerances and quality standards as our Natural Polypropylene fittings. WP is not a USP Class VI material and does not offer lot tractability. RoHS compliant.

WHITE NYLON (WN)

White Nylon has the same chemical and physical properties as Natural Nylon. WN fittings contain recycled runner material produced during virgin material, Natural Nylon production runs. White Nylon fittings are manufactured to the same tolerances and quality standards as our Natural Nylon fittings. WN and does not offer a lot of tractability. RoHS compliant.

DISCLAIMER

Data presented for properties of materials, pressure, temperature and chemical resistance is for reference only. Customer applications and conditions of use are beyond our control; therefore, it is imperative that customers test Eldon James products in their specific application to determine suitability. All information is provided without implied or expressed warranty or guarantee, and none of the information provided constitutes a recommendation or endorsement of any kind by Eldon James Corporation.