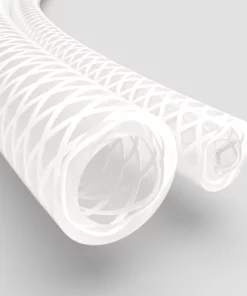

Flexelene 135C Braided Tubing

INTRODUCING NEW SILICONE ALTERNATIVE BRAIDED TUBING.

Our braided tubing is engineered expressly as a silicone alternative for high-purity fluid applications in the biomedical and pharmaceutical industries.

Braided Flexelene™ 135C was developed to meet the critical demands of bioprocess, medical, and laboratory applications. This newly formulated TPE (thermoplastic elastomer) tubing is an excellent alternative to silicone.

FLXCBR135C tubing is durable and an excellent choice for high-pressure applications. Sterilized by Ethylene Oxide (EtO), Gamma resistance to 45 kGy, Autoclave to 135C, temperature range -44°C to 135°C (-47°F to 275°F), RoHS Compliant, Shore A 68 Hardness.

Manufactured for ultra-pure fluid transfer and meets a diverse range of pharmaceutical, medical and bioprocessing applications. Braided Flexelene™ 135C meets the requirements of REACH, RoHS, USP 661, CFR, USP VI, ISO 9001:2015 and 13485:2016, and other special test requirements.

Flexelene™ 135C Braided Reinforced Tubing with 1/4" ID x 1/2" OD in a 15' Length

Flexelene™ 135C Braided Reinforced Tubing with 1/4" ID x 1/2" OD in a 25' Length

Flexelene™ 135C Braided Reinforced Tubing with 1/4" ID x 1/2" OD in a 50' Length

Flexelene™ 135C Braided Reinforced Tubing with 3/8" ID x 5/8" OD in a 15' Length

Product Features:

- Superior Bio Compatibility

- No Halogens or Phthalates

- High Pressure Rating

- Extremely Flexible

- Ultra-low Extractables / Leachables

- Non-pyrogenic Material

- Non-Animal Derived

- Ultra-Pure Medical Grade

- Excellent resilience and bend radius.

- Material Certificate and Lot Traceability

Certifications:

- USP Class VI biocompatibility requirements

- USP 661

- Cytotoxicity Criteria

- CFR Title 21 Section 177.2600

- ISO 10993 (part 4 and 5)

- Fully Lot Traceable

- Animal Derived Ingredient Free

Typical Applications:

- Pharmaceutical and biotech processing

- Single-use systems

- High volume ultra-pure

- fluid transfer

- Media processing

- Sterile filling

- Laboratory use

- Skid transfers

- Processing lines

Sterilization:

- E-beam/Gamma 25 to 45 kGy, no deficiencies, may color shift at higher doses.

- EtO No issues. It can safely be used.

- Autoclave Up to 135°C.

Flexelene™ 135C Braided Reinforced Tubing with 5/8" ID x 1" OD in a 15' Length

Flexelene™ 135C Braided Reinforced Tubing with 5/8" ID x 1" OD in a 25' Length

Flexelene™ 135C Braided Reinforced Tubing with 5/8" ID x 1" OD in a 50' Length

Flexelene™ 135C Braided Reinforced Tubing with 3/4" ID x 1.125" OD in a 15' Length

Thermoplastic Elastomer (TPE) Tubing

TPE (thermoplastic elastomer) tubing in the life sciences and pharmaceutical industries is becoming increasingly popular due to its numerous benefits over traditional silicone tubing. TPE tubing is an excellent choice for many applications due to its flexibility, strength, low cost, and reliability. TPE tubing is also a perfect choice for companies looking to reduce costs while maintaining high performance.

TPE tubing is flexible, allowing its use in various applications. It can bend and twist without kinking or deforming and is exceptionally reliable. It is resistant to corrosion and is unlikely to degrade over time, making it ideal for long-term applications. It is also resistant to many chemicals, which makes it an excellent choice for applications that require frequent cleaning or sterilization.

Furthermore, TPE tubing is also much more robust than silicone tubing. It can withstand higher pressure levels and is more resistant to tearing and puncturing. These features make it an ideal choice for applications that require high levels of durability and strength.